.gtr-container-def456 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 15px;

max-width: 100%;

box-sizing: border-box;

border: none !important;

}

.gtr-container-def456 * {

box-sizing: border-box;

}

.gtr-container-def456 .gtr-title-main {

font-size: 16px;

font-weight: bold;

margin-bottom: 15px;

color: #2c3e50;

text-align: left;

}

.gtr-container-def456 .gtr-title-sub {

font-size: 15px;

font-weight: bold;

margin-top: 20px;

margin-bottom: 10px;

color: #34495e;

text-align: left;

}

.gtr-container-def456 p {

font-size: 14px;

margin-top: 0;

margin-bottom: 10px;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-def456 ol,

.gtr-container-def456 ul {

list-style: none !important;

margin: 0 !important;

padding: 0 !important;

margin-bottom: 15px !important;

}

.gtr-container-def456 li {

font-size: 14px;

margin-bottom: 8px;

padding-left: 25px;

position: relative;

text-align: left;

}

.gtr-container-def456 ol li::before {

content: counter(list-item) ".";

counter-increment: none;

position: absolute;

left: 0;

top: 0;

font-weight: bold;

color: #007bff;

width: 20px;

text-align: right;

}

.gtr-container-def456 ul li::before {

content: "•";

position: absolute;

left: 0;

top: 0;

font-weight: bold;

color: #007bff;

font-size: 18px;

line-height: 1;

}

.gtr-container-def456 .gtr-separator {

border-top: 1px solid #ddd;

margin: 30px 0;

}

.gtr-container-def456 .gtr-table-wrapper {

width: 100%;

overflow-x: auto;

margin-bottom: 15px;

}

.gtr-container-def456 table {

width: 100%;

border-collapse: collapse !important;

border-spacing: 0 !important;

margin-bottom: 15px;

font-size: 14px;

color: #333;

}

.gtr-container-def456 th,

.gtr-container-def456 td {

border: 1px solid #ccc !important;

padding: 8px 12px !important;

text-align: left !important;

vertical-align: top !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-def456 th {

font-weight: bold;

background-color: #f0f0f0;

color: #2c3e50;

}

.gtr-container-def456 tr:nth-child(even) {

background-color: #f9f9f9;

}

.gtr-container-def456 img {

max-width: 100%;

height: auto;

display: block;

margin: 0 auto 15px auto;

}

.gtr-container-def456 .gtr-image-group {

display: block;

margin-bottom: 15px;

}

.gtr-container-def456 video {

max-width: 100%;

height: auto;

display: block;

margin: 0 auto 15px auto;

}

@media (min-width: 768px) {

.gtr-container-def456 {

padding: 25px;

max-width: 800px;

margin: 0 auto;

}

.gtr-container-def456 .gtr-title-main {

font-size: 18px;

margin-bottom: 20px;

}

.gtr-container-def456 .gtr-title-sub {

font-size: 16px;

margin-top: 25px;

margin-bottom: 12px;

}

.gtr-container-def456 p {

margin-bottom: 12px;

}

.gtr-container-def456 li {

margin-bottom: 10px;

}

.gtr-container-def456 .gtr-image-group {

display: flex;

flex-wrap: wrap;

gap: 15px;

}

.gtr-container-def456 .gtr-image-group .gtr-image-item {

flex: 1 1 calc(50% - 7.5px);

max-width: calc(50% - 7.5px);

}

}

Core Advantages of Titanium (Why is Titanium "Beloved" in Aerospace?)

1.Exceptional Strength-to-Weight Ratio (High Strength, Low Density): Titanium has a density of about 4.5 g/cm³, which is only 60% that of steel, yet its strength is comparable to many high-strength steels. This means that for the same strength and stiffness requirements, using titanium alloys can significantly reduce weight compared to steel. Weight reduction is a perpetual theme in aerospace; every kilogram saved translates to substantial fuel efficiency, longer range, or greater payload capacity.

2.Excellent Corrosion Resistance: A dense, stable oxide layer (TiO₂) forms on the surface of titanium, giving it极高的 resistance to atmosphere, seawater, and chemicals common in aerospace (like hydraulic fluid and de-icing fluid). Its corrosion resistance is far superior to stainless steel. This greatly enhances component lifespan and reliability while reducing maintenance costs.

3.Good High-Temperature Performance: Conventional titanium alloys (like Ti-6Al-4V) can operate stably long-term at 400-500°C, while some specialized high-temperature titanium alloys (like Ti-Al intermetallic compounds) can withstand temperatures up to 600°C and above. This makes it ideal for hot-section components of aircraft engines.

4.Compatibility with Composite Materials: Titanium has an electrochemical corrosion potential similar to Carbon Fiber Reinforced Polymer (CFRP) composites. When the two are in contact, they do not suffer from severe galvanic corrosion. Therefore, titanium is often used for fasteners, brackets, and junctions connected to composite components.

Main Application Areas

1. Aircraft Engines – The Largest Market for Titanium

The engine is the "heart" of an aircraft and the component with the highest usage of titanium alloys (accounting for about 25%-40% of the engine's total weight).

Fan Blades: The front fan blades of modern high-thrust turbofan engines (like the LEAP, GEnx) commonly use titanium alloys. They require extremely high strength to withstand enormous centrifugal forces and potential foreign object impacts.

Compressor Discs and Blades: Discs, blades, and casings in the low-pressure stages of the compressor extensively use titanium alloys. These components operate in high-temperature, high-pressure environments, demanding materials with high strength, fatigue resistance, and creep resistance.

Engine Nacelles and Struts: These structural components also use significant amounts of titanium alloy for weight reduction.

2. Airframe Structures

In the aircraft airframe, titanium alloys are used for critical load-bearing structures, particularly in areas where traditional aluminum alloys cannot meet requirements.

Landing Gear Components: The landing gear must withstand the immense impact forces during landing and static loads, making it one of the highest-load components on an aircraft. High-strength titanium alloys (like Ti-10V-2Fe-3Al) are used to manufacture critical landing gear beams, struts, and torque links.

Wing and Fuselage Junctions: Critical load-bearing components like the center wing box connecting the wings to the fuselage, flap tracks, and keel beams often use high-strength titanium alloy forgings due to concentrated loads.

Fasteners: Titanium alloy rivets, bolts, screws, and other fasteners are widely used because they are strong, lightweight, and corrosion-resistant.

Hydraulic Systems and Pipelines: Due to titanium's excellent corrosion resistance, it is often used to manufacture complex hydraulic pipeline systems, ensuring long-term reliability.

3. Spacecraft

In the space sector, the benefits of weight reduction are even more significant (directly related to launch capacity), alongside the need to withstand extreme temperature environments and the vacuum of space.

Rocket Engines: Components of liquid-fueled rocket engines like propellant tanks, turbopumps, and injectors use titanium alloys to withstand the corrosion of cryogenic liquid oxygen/hydrogen and high pressures.

Pressure Vessels: Titanium alloy gas cylinders used for storing high-pressure gases (like helium) and propellants are lightweight, have high pressure resistance, and offer good reliability.

Satellite Structures: Satellite brackets, connection frames, camera mirror barrels, and other structural components use titanium alloys to meet stringent requirements for structural stability, lightweight design, and high stiffness in the space environment.

Manned Spacecraft: Crewed spacecraft like the Shenzhou and Soyuz use titanium alloys extensively in the load-bearing structures of their return modules.

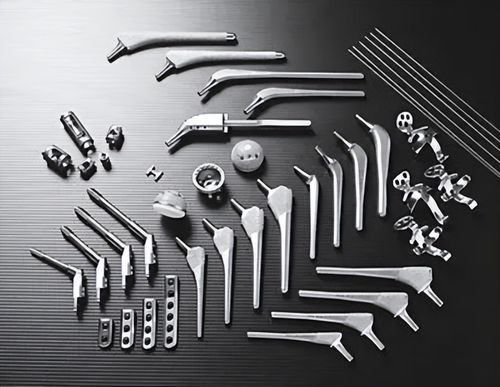

Titanium is primarily used in the following areas:

1. Orthopedic ImplantsThis is the most extensive and well-established application of titanium.

Artificial Joints: Hip joints, knee joints, shoulder joints, elbow joints, etc. Critical load-bearing components such as femoral stems and acetabular cups are largely made of titanium alloys.

Trauma Repair: Bone plates, screws, and intramedullary nails for internal fracture fixation. These devices stabilize fractures and promote bone healing.

Spinal Fusion: Interbody fusion devices, titanium mesh, and pedicle screw systems used in surgeries for scoliosis correction and disc replacement.

2. Dental Implants and Prosthetics

Dental Implants: Titanium implants are the "gold standard" in dentistry. They are embedded into the jawbone to serve as artificial roots, forming a strong osseointegration with the bone, onto which crowns are later mounted.

Denture Frameworks: Metal frameworks for removable dentures, as well as bases for crowns and bridges, often use titanium due to its lightness, durability, and low allergenicity.

Orthodontic Appliances: Some orthodontic brackets and archwires are also made from titanium alloys.

3. Cardiovascular Interventional Devices

Pacemaker and Defibrillator Casings: Titanium casings provide excellent sealing, protecting internal精密 electronic components while being biocompatible with human tissues, reducing rejection reactions.

Vascular Stents: Although cobalt-chromium alloys and biodegradable materials are currently mainstream, nickel-titanium alloys (Nitinol) are used for self-expanding vascular stents due to their unique superelasticity and shape memory effect, particularly in areas like the carotid and lower limb arteries.

4. Surgical Instruments and Equipment

Surgical Instruments: Titanium forceps, scissors, retractors, etc., are lighter than stainless steel instruments, offer high fatigue strength, and are corrosion-resistant, able to withstand repeated high-temperature sterilization.

Medical Device Components: Internal components of MRI scanners, robotic surgical arms, etc. Titanium’s non-magnetic property is crucial for safety in MRI environments and avoids imaging interference.

5. Craniofacial Reconstruction

Titanium meshes and plates used to repair skull and facial bone defects caused by trauma or surgery. They can be precisely shaped to restore both function and appearance.

2. Core Advantages of Titanium Materials

Titanium’s irreplaceable role in the medical field stems from its exceptional properties:

1. Excellent BiocompatibilityThis is titanium’s most important advantage. Its surface naturally forms a dense, stable titanium oxide passive film that is chemically inert, rarely reacting with human tissues or fluids. This prevents inflammation, allergies, or rejection reactions. It enables direct and functional bonding with living bone tissue, known as osseointegration, which is critical for the long-term stability of implants.

2. High Strength-to-Weight Ratio and Low Elastic Modulus

High Strength-to-Weight Ratio: Titanium’s strength is comparable to many steels, but its density (~4.5 g/cm³) is only about 60% that of steel, making implants lighter and reducing the patient’s burden.

Low Elastic Modulus: Titanium’s elastic modulus (~110 GPa) is closer to that of human bone (10-30 GPa) and much lower than stainless steel or cobalt-chromium alloys. This reduces the stress shielding effect—where stiff implants bear most of the stress, causing surrounding bone to become porous and resorb due to lack of mechanical stimulation. Titanium implants allow more natural stress transfer to the bone, promoting healing and long-term stability.

3. Outstanding Corrosion ResistanceBody fluids are a corrosive environment containing chloride ions (e.g., sodium chloride). Titanium’s passive film gives it extremely high corrosion resistance in physiological environments, making it nearly impervious to corrosion. This means:

Long Implant Lifespan: No failure due to corrosion.

High Biocompatibility: Avoids tissue toxicity and allergic reactions (e.g., nickel allergies) caused by metal ion release.

4. Non-Magnetic PropertyTitanium is paramagnetic and does not magnetize in strong magnetic fields. This allows patients with titanium implants to safely undergo MRI scans without concerns about implant heating, displacement, or imaging interference, which is vital for post-operative diagnosis and monitoring.

5. Good Machinability and FormabilityAlthough pure titanium is soft, alloying (e.g., with aluminum and vanadium to form Ti-6Al-4V) and advanced processing techniques enable the production of complex-shaped implants to meet personalized surgical needs. The shape memory effect of nickel-titanium alloys offers unique solutions for applications like self-expanding stents.

Summary and Future Outlook

Property

Advantage

Application Example

Biocompatibility

Non-toxic, non-allergenic, osseointegration

Long-term safety of all implants

Mechanical Properties

Lightweight, high strength, reduced stress shielding

Excellent load-bearing capacity in joints, spines, and bone plates while protecting bone

Corrosion Resistance

Long lifespan, minimal ion release

Long-term stability and high safety in the body

Non-Magnetic Property

Safe for MRI scans

Facilitates post-operative imaging follow-up

Processability

Can be shaped into complex forms

Customized implants and minimally invasive surgical instruments

Future Trends:

In summary, due to their excellent corrosion resistance, high strength, long service life, and exceptional eco-friendliness, titanium flanges are becoming critical components in demanding environmental engineering projects, especially in scenarios involving corrosive media and requiring long-term equipment stability.

I. Specific Applications of Titan Flates in Environmental Protection

Titanium flanges, as essential connecting components in piping systems used to join pipes, valves, and equipment, ensuring system sealing and structural integrity, are primarily used in the following highly corrosive environments within the environmental sector:

Flue Gas Desulfurization (FGD) Systems

Application Scenario: Tail gas treatment systems in thermal power plants, waste incineration plants, and metallurgical/chemical industries. These flue gases contain large amounts of sulfur dioxide (SO₂), chlorides (e.g., HCl), fluorides, and moisture, creating highly corrosive acidic environments (e.g., dilute sulfuric acid, sulfurous acid).

Role: Titanium flanges are used to connect absorbers, ducts, spray systems, and recirculation piping within FGD systems. They are critical connection points ensuring the entire corrosive gas handling system remains leak-free.

Industrial Wastewater Treatment Systems

Application Scenario: Treatment plants for high-concentration wastewater from chemical, pharmaceutical, electroplating, printing, dyeing, and paper industries. This wastewater often contains chloride ions (Cl⁻), strong acids (e.g., hydrochloric acid, sulfuric acid), strong alkalis, oxidizing chemicals, etc.

Role: Titanium flanges connect reaction kettles, sedimentation tanks, filtration units, advanced oxidation (e.g., ozone treatment) pipelines, and wastewater conveyance pipes, particularly in areas requiring resistance to chloride-induced stress corrosion cracking (SCC).

Seawater Desalination Systems

Application Scenario: Seawater desalination plants using reverse osmosis (SWRO) and multi-effect distillation (MED). Seawater is a natural strong electrolyte containing high concentrations of chloride ions, which are extremely corrosive to most metals.

Role: Titanium flanges are widely used in seawater intake pipes, pretreatment systems, connections for high-pressure reverse osmosis membrane housings, and connecting parts for heat exchange systems in distillation units.

Hazardous Waste Treatment

Application Scenario: Treatment facilities for hazardous waste liquids containing acids, alkalis, or organic solvents.

Role: Ensure absolute safety and reliability at pipeline connection points during the transport and treatment of these extremely hazardous media, preventing leaks of harmful substances.

Hydrometallurgy and Chemical Processing

Application Scenario: Although more industrial, their environmental end-of-pipe treatment is closely related. Used in processes involving chlorine, hydrochloric acid, aqua regia, etc., for reactions and extraction.

Role: Used for connections between equipment and piping, ensuring the containment of production and recycling processes.

II. Core Advantages of Titanium Flanges

Titanium (especially commercial pure grades like GR2, GR1) offers irreplaceable advantages compared to other materials like stainless steel (e.g., 304, 316L), duplex steel, and nickel-based alloys (e.g., Hastelloy) in environmental applications:

Superior Corrosion Resistance (Core Advantage)

Resistance to Chloride Ion Corrosion: This is titanium's most prominent advantage. Titanium has innate immunity to pitting and stress corrosion cracking (SCC) caused by chloride ions, whereas stainless steel is very vulnerable. This grants it an extremely long service life when handling seawater, chloride-containing wastewater, and flue gas (containing HCl).

Resistance to Acidic Environments: Titanium performs well in oxidizing acids (e.g., nitric acid, chromic acid) and weak reducing acids. Although it corrodes faster in non-oxidizing acids (e.g., pure hydrochloric acid, sulfuric acid), in FGD environments, the presence of oxidants (e.g., SO₂, O₂) prompts the rapid formation of a dense, stable titanium oxide (TiO₂) passive film on the surface, effectively halting further corrosion.

Resistance to Crevice Corrosion: Flange connections are prone to crevice corrosion. Titanium's resistance to crevice corrosion in high-chloride environments is far superior to stainless steel.

Excellent Mechanical Strength and Light Weight

Titanium has high strength but a density (~4.51 g/cm³) much lower than steel (~7.9 g/cm³). This means for the same strength requirements, titanium flanges can be made lighter, helping reduce system load, which is particularly advantageous for large absorbers or elevated ducts.

Long Service Life and Low Lifecycle Cost (LCC)

Although the initial material cost of titanium is higher than stainless steel, its virtually maintenance-free nature, extremely low failure rate, and超长 service life (20-30 years or more, whereas stainless steel might need replacement in a few years) significantly reduce the total cost of ownership.

It avoids massive production losses and secondary investments caused by downtime for replacement and repairs, making it highly economical in the long run.

Excellent Eco-friendliness and Safety

Biocompatibility: Titanium is non-toxic and harmless, with good compatibility with human tissue and the environment. Even if corrosion products enter the system, they do not cause secondary pollution, making it very suitable for water treatment where effluent quality is critical.

High Safety: Its high reliability greatly reduces the risk of pipeline failure and leakage of hazardous substances due to corrosion, which is crucial for protecting the environment and operator safety.

Good Fabrication Properties

Titanium flanges can be manufactured through forging, casting, etc., meeting various pressure ratings (PN6-PN100) and standards (GB, ASME, JIS, etc.).

III. Comparison with Other Materials

Property

Titanium (GR2)

316L Stainless Steel

Duplex Steel 2205

Hastelloy C-276

Cl⁻ Corrosion Resistance

Excellent

Poor (Prone to pitting/SCC)

Good (But still limited)

Excellent

Initial Cost

High

Low

Medium

Very High

Lifecycle Cost

Low

High (Frequent replacement)

Medium

High

Density / Weight

Low / Light

High / Heavy

High / Heavy

Very High / Very Heavy

Applicable pH Range

Wide

Narrow

Medium

Specific Applications in the Chemical Industry

Titanium materials are used in almost all chemical sub-sectors involving highly corrosive media, primarily in the form of reactors, pressure vessels, heat exchangers, towers, pipelines, fittings, valves, pumps, agitators, and electrodes.

Here are some typical application scenarios:

1. Chlor-Alkali Industry (Largest Chemical Application)

The chlor-alkali industry produces caustic soda, chlorine, and hydrogen, all of which are highly corrosive media.

Application Equipment:

Ion-Membrane Electrolyzers: Titanium is used as the core material for the anode chamber (exposed to chlorine, hydrochloric acid, and hypochlorous acid), anode plates, and cooling pipes. This is the largest application of titanium in the chemical industry.

Wet Chlorine Gas Coolers/Heat Exchangers: The corrosion resistance of titanium makes it the only economically viable metal material for manufacturing shell-and-tube or plate-type coolers for high-temperature wet chlorine gas.

Chlorine Gas Scrubbers, Drying Towers, and Delivery Pipelines: Titanium is widely used throughout the system handling wet and dry chlorine gas.

2. Soda Ash (Sodium Carbonate) Industry

Application Equipment:

External Coolers, Condensers, and Coolers: In the soda ash production process, the media contain high concentrations of chloride ions (Cl⁻) and ammonium ions (NH₄⁺), which cause severe pitting and stress corrosion in stainless steel. Titanium heat exchangers perfectly solve this problem, with a service life of over 20 years, compared to just 1-2 years for stainless steel equipment.

3. Urea Industry

Application Equipment:

Urea Synthesis Towers, High-Pressure Heat Exchangers, and Stripping Towers: Urea production occurs under high temperature and pressure, and the intermediate product, ammonium carbamate, is highly corrosive. Early use of stainless steel required oxygen passivation protection and had limited service life. The adoption of titanium-lined or all-titanium equipment significantly extends service life and improves safety and reliability.

4. Nitric Acid Industry

Application Equipment:

Nitric Acid Reboilers, Condensers, Heating Coils, Pumps, and Valves: Titanium exhibits excellent stability in nitric acid of various concentrations and temperatures (except fuming nitric acid), with corrosion resistance superior to stainless steel and aluminum alloys.

5. Organic and Fine Chemicals

Application Equipment:

Reaction Kettles (with Jackets or Coils) and Coils: Used in the production of pesticides, dyes, pharmaceutical intermediates, cosmetics (e.g., acetic acid environments), etc. Whenever corrosive media such as chlorides, hydrochloric acid, or organic acids are involved, titanium equipment provides a pure reaction environment, avoiding metal ion contamination of products.

PTA (Purified Terephthalic Acid) Production: Titanium is a key material for manufacturing reactors and heat exchangers in acetic acid media.

6. Seawater Cooling and Desalination

Application Equipment:

Seawater Coolers for Power Plants and Chemical Plants: Titanium tube heat exchangers are standard equipment for coastal power plants and chemical plants due to their unmatched resistance to seawater erosion and corrosion.

Seawater Desalination Plants: The heat transfer tubes in multi-stage flash (MSF) or low-temperature multi-effect (MED) desalination plants almost exclusively use titanium tubes to ensure long-term stable water production rates.

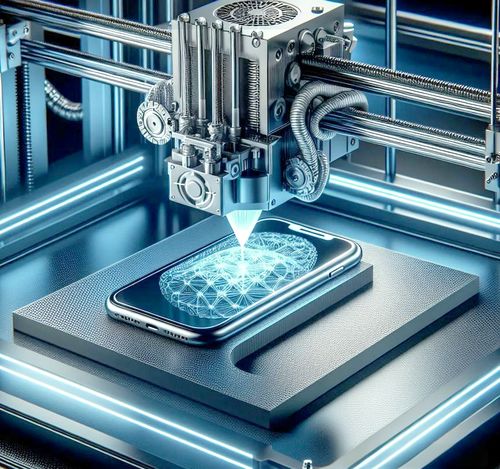

Core Advantages of Titanium in 3D Printing

3D printing technology perfectly addresses many of the pain points of traditional titanium alloy processing and maximizes its advantages.

Overcomes Traditional Manufacturing Challenges, Enables "Freeform Fabrication"

Advantage: Traditionally, titanium parts rely heavily on forging and machining (CNC), resulting in very low material utilization (often "buy a kilo of ingot, mill away nine-tenths"), high costs, and long lead times. 3D printing is a near-net-shape technology, producing almost no material waste and requiring only minimal post-processing, making it ideal for expensive high-performance materials.

Advantage: It breaks the constraints of traditional manufacturing, enabling the production of highly complex internal cavities, irregular channels, and monolithic structures that are impossible with subtractive methods.

Great Design Freedom and Lightweighting Potential

Advantage: Combined with topology optimization and lattice structure design, 3D printing can create extremely lightweight parts with excellent mechanical properties. For example, replacing a solid interior with a sturdy mesh structure can significantly reduce weight while maintaining strength, which is crucial for the aerospace industry's "gram-shaving" philosophy.

Cost Advantage for Low-Volume, Customized Production

Advantage: Traditional casting or forging requires expensive molds and fixtures, making it suitable only for mass production. 3D printing requires no molds; digital files can directly drive production. It is particularly suited for low-volume, customized products (e.g., medical implants, satellite parts, prototypes), where the unit cost remains almost unchanged.

Excellent Material Properties and Density

Advantage: The primary technologies for printing titanium are Selective Laser Melting (SLM) and Electron Beam Melting (EBM). These techniques use high-energy sources to completely melt and fuse metal powder layer by layer. The resulting parts can achieve densities exceeding 99.7%, with mechanical properties (strength, fatigue resistance) that surpass traditional castings and are comparable to forgings.

Functional Integration and Simplified Production

Advantage: Complex assemblies that originally consisted of multiple parts can be printed integrally in a single piece. This reduces assembly requirements, eliminates potential weak points (e.g., welds, rivets), and improves the overall reliability and performance of the product.

Summary Comparison

Feature

Traditional Machining (Forging/CNC)

3D Printing (Additive Manufacturing)

Material Utilization

Low (5%-10% waste is common)

Very High (near 100%)

Design Complexity

Limited

Nearly Unlimited Freedom

Production Lead Time

Long (requires tooling/fixtures)

Short (direct from digital file)

Customization Cost

Very High

Relatively Low

Suitable Batch Size

Mass Production

Low-Volume, Customized

Integral Forming

Difficult, requires assembly

Easy, can be printed as one piece

In conclusion, 3D printing technology has transformed titanium from a "difficult-to-process high-performance material" into an "intelligent material capable of achieving extreme designs." It is not only a revolution in manufacturing methods but also a leap in design philosophy, greatly expanding the application boundaries of titanium alloys in high-tech fields.

High-strength titanium alloy rods are critical engineering materials renowned for their exceptional strength-to-weight ratio, excellent corrosion resistance, and ability to perform under extreme conditions. These properties make them indispensable across a wide range of industries, particularly where lightweight durability and reliability are paramount. Below, we explore the key applications of high-strength titanium alloy rods in detail.

1. Aerospace Industry

The aerospace sector is the largest consumer of high-strength titanium alloy rods. These rods are used in the manufacture of critical components such as:

Engine Parts: Titanium alloys like Ti-6Al-4V (Grade 5) are used in jet engine components, including compressor blades, fan disks, and rotor shafts. Their high strength and heat resistance (up to 600°C) ensure efficiency and safety in demanding environments.

Airframe Structures: Titanium rods are employed in landing gear, wing supports, and fasteners, reducing weight while maintaining structural integrity. This weight savings translates to improved fuel efficiency and payload capacity.

Spacecraft and Missiles: Their resistance to extreme temperatures and corrosion makes titanium alloys ideal for rocket motor casings, satellite components, and missile bodies.

2. Medical and Healthcare

Titanium’s biocompatibility and resistance to bodily fluids make it a preferred material for medical devices:

Orthopedic Implants: Rods made from alloys like Ti-6Al-4V ELI (Extra Low Interstitial) are used in spinal fusion devices, bone plates, and joint replacements. Their strength and flexibility mimic natural bone, promoting faster healing.

Surgical Instruments: Titanium rods are machined into lightweight, durable tools that withstand repeated sterilization without corroding.

Dental Implants: Their non-toxic nature and osseointegration properties ensure long-term stability in dental applications.

3. Marine and Offshore Engineering

The marine environment’s corrosive nature demands materials with exceptional resistance:

Shipbuilding: Titanium rods are used in propeller shafts, heat exchangers, and submarine hulls, reducing maintenance costs and extending service life.

Offshore Oil and Gas: Components like drilling risers and valve systems benefit from titanium’s resistance to seawater and sour gas (H₂S) corrosion.

4. Chemical and Process Industries

Titanium alloys withstand aggressive chemicals and high temperatures:

Reactors and Heat Exchangers: Rods are used to construct equipment handling chlorides, acids, and other corrosive substances.

Piping and Valves: Titanium’s durability ensures leak-free performance in chemical processing plants.

5. Automotive and Motorsports

High-performance vehicles leverage titanium’s lightweight strength:

Engine Components: Connecting rods, valves, and exhaust systems reduce weight, enhancing speed and fuel efficiency.

Racing and Luxury Cars: Titanium rods are used in suspension systems and chassis reinforcements to improve handling and durability.

6. Sports and Consumer Goods

Sports Equipment: Golf club shafts, bicycle frames, and登山 gear utilize titanium rods for lightweight strength and impact resistance.

High-End Electronics: In devices like laptops and cameras, titanium rods provide structural support without adding bulk.

7. Energy Sector

Nuclear Power: Titanium alloys are used in heat exchangers and cooling systems due to their radiation resistance and stability at high temperatures.

Renewable Energy: Wind turbine components and hydrogen storage systems benefit from titanium’s corrosion resistance and durability.

8. Defense and Military

Armored Vehicles: Titanium rods enhance armor protection while reducing weight.

Firearms and Artillery: Lightweight, durable components improve mobility and performance.

Conclusion

High-strength titanium alloy rods are versatile materials driving innovation across industries. Their unique combination of lightness, strength, and corrosion resistance makes them ideal for applications where failure is not an option. As technology advances, the demand for these rods is expected to grow, particularly in emerging fields like additive manufacturing and renewable energy.

Titanium, as a material in tubing fittings, exhibits stable chemical properties and excellent biocompatibility. It offers high corrosion resistance and stability, making it a metal that has no adverse effects on the human body and does not trigger allergic reactions.

The characteristics of titanium tubing fittings are primarily reflected in the following aspects:

Corrosion ResistanceTitanium tubing fittings possess exceptional corrosion resistance. Even when exposed to humid air or seawater, their corrosion resistance significantly surpasses that of stainless steel. Therefore, users need not worry about lifespan issues—titanium tubing fittings are 15 times more corrosion-resistant than stainless steel and have a service life approximately 10 times longer.

Low-Temperature ResistanceTitanium tubing fittings maintain their mechanical properties even under low-temperature conditions, making them highly resistant to cold environments.

High StrengthThe density of titanium alloys is typically around 4.51 g/cm³, which is only 60% that of steel. Despite this, titanium tubing fittings exhibit remarkably high strength, far exceeding that of other metallic structural materials.

High Thermal StrengthTitanium tubing fittings demonstrate excellent thermal strength, maintaining stability even after prolonged exposure to temperatures of 450–500°C. In general, titanium alloys can operate at temperatures up to 500°C, whereas aluminum alloys are typically limited to 200°C.

Smooth Surface and Anti-Fouling PropertiesTitanium, with its low density and lightweight nature, features a smooth surface that res scaling. The use of titanium tubing fittings in daily applications significantly reduces the scaling coefficient.

Thanks to these five key characteristics, titanium tubing fittings are widely used in industries such as chemical equipment, offshore power generation facilities, seawater desalination systems, ship components, and the electroplating industry.

.gtr-container-f7d9e2 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 16px;

max-width: 960px;

margin: 0 auto;

box-sizing: border-box;

}

.gtr-container-f7d9e2 .gtr-intro-statement {

font-size: 18px;

font-weight: bold;

margin-bottom: 24px;

color: #0056b3;

text-align: left !important;

}

.gtr-container-f7d9e2 .gtr-section-title {

font-size: 18px;

font-weight: bold;

margin-top: 32px;

margin-bottom: 16px;

color: #2c3e50;

text-align: left !important;

}

.gtr-container-f7d9e2 p {

font-size: 14px;

margin-bottom: 16px;

text-align: left !important;

}

.gtr-container-f7d9e2 ol {

list-style: none !important;

margin: 0 0 16px 0 !important;

padding: 0 !important;

}

.gtr-container-f7d9e2 ol li {

position: relative;

padding-left: 30px;

margin-bottom: 12px;

font-size: 14px;

text-align: left !important;

}

.gtr-container-f7d9e2 ol li::before {

content: counter(list-item) ".";

counter-increment: none;

position: absolute;

left: 0;

top: 0;

font-weight: bold;

color: #0056b3;

width: 20px;

text-align: right;

}

.gtr-container-f7d9e2 ol li p {

margin: 0;

text-align: left !important;

}

.gtr-container-f7d9e2 strong {

font-weight: bold;

}

@media (min-width: 768px) {

.gtr-container-f7d9e2 {

padding: 24px 40px;

}

}

Replacing traditional steel, titanium chamber bodies offer exceptional biocompatibility, superior corrosion resistance, and lightweight properties, revolutionizing the experience for patients and medical staff

Recently, a series of large medical hyperbaric oxygen chamber groups made from advanced titanium plates were successfully installed, tested, and officially put into clinical use at several top-tier hospitals in China, including Beijing Tiantan Hospital affiliated with Capital Medical University, Ruijin Hospital affiliated with Shanghai Jiao Tong University School of Medicine, and the Chinese People's Liberation Army General Hospital (301 Hospital). The deployment of these high-end medical facilities has not only significantly increased the overall capacity and efficiency of hyperbaric oxygen therapy but has also earned high praise from both medical professionals and patients for their exceptional safety and unprecedented comfort. This marks a new era in China's hyperbaric oxygen medical infrastructure, characterized by the adoption of titanium technology.

1. Why Choose Titanium? A Material Revolution Overturning Tradition

Traditional hyperbaric oxygen chambers are mostly made of steel. While the technology is mature, it has inherent drawbacks: heavy weight, high requirements for installation foundations, and susceptibility to oxidation and corrosion in long-term high-oxygen, high-humidity environments. This leads to high maintenance costs and potential safety risks. Additionally, strong metal thermal conductivity makes the internal temperature easily affected by external conditions, reducing comfort.

The introduction of titanium metal perfectly addresses these issues:

Ultimate Safety and Durability: Titanium is a highly reactive metal, but its surface instantly forms a dense and stable titanium oxide passive film. This film gives titanium plates unparalleled corrosion resistance, enabling them to fully withstand the erosion of high-concentration oxygen, high humidity, and disinfectants inside hyperbaric oxygen chambers. This fundamentally eliminates safety risks caused by corrosion-induced strength degradation, with a design lifespan far exceeding that of steel chambers. Its high strength and low density also make the chamber body lighter while ensuring safety.

Excellent Biocompatibility and Comfort: Titanium is known as a "bio-friendly metal" and is widely used in implants such as artificial joints and heart valves. Using titanium for chamber manufacturing ensures that no harmful substances are released, guaranteeing the purity of the air inside the chamber. Moreover, titanium's low thermal conductivity effectively reduces "condensation" inside the chamber, keeping the walls dry and maintaining a stable internal temperature. This greatly enhances patient comfort during lengthy treatments, reducing discomfort such as stuffiness and humidity.

Modern Aesthetics and Humanized Design: Titanium plates have a modern silver-gray appearance that requires no additional coating, giving them a sleek and high-end look. Combined with large transparent observation windows, comfortable aviation-style seats, integrated entertainment systems, and intelligent environmental control systems, patients are provided with a bright, spacious, and pleasant treatment environment, effectively alleviating claustrophobia.

2. Clinical Feedback: unanimous Praise from Medical Professionals and Patients

At the Hyperbaric Oxygen Department of Beijing Tiantan Hospital, Mr. Wang, who had just finished treatment, said, "It feels completely different from the old-style chamber I was in before. It’s not stuffy at all—very dry and comfortable, like being in a premium aircraft cabin. Watching TV makes the time pass quickly, and it’s even relaxing."

A chief physician at Ruijin Hospital's Hyperbaric Oxygen Department explained, "The adoption of titanium chamber groups is a qualitative leap for our department. First and foremost is safety—we no longer have to worry about chamber corrosion, and daily maintenance工作量 is significantly reduced. Second is efficiency—large chamber groups can treat more patients simultaneously, and the optimized treatment environment significantly improves patient compliance, which is crucial for neurorehabilitation patients requiring long-term treatment. This is also an important part of our hospital’s efforts to build a 'future hospital' and enhance the quality of medical services."

3. Representing High-End Chinese Medical Equipment on the Global Stage

The titanium hyperbaric oxygen chamber groups recently put into use were independently developed and manufactured by leading domestic pressure vessel manufacturers and medical device companies. This fully demonstrates that China has achieved world-class advanced levels in high-end titanium processing (such as large-area titanium plate welding technology and precision forming technology) and specialized medical equipment design.

Previously, the high-end hyperbaric oxygen chamber market was long dominated by a few foreign brands. The successful application of domestic titanium chambers not only achieves import substitution and reduces procurement costs for medical institutions but also,凭借其优异性能, forms strong international competitiveness, already attracting attention from overseas customers.

Conclusion:

The widespread application of titanium hyperbaric oxygen chamber groups is a classic case of new material technology innovation driving medical equipment upgrades and ultimately benefiting public welfare. It is not merely a simple material replacement but also reflects a patient-centered medical philosophy that pursues higher safety standards and better service experiences. With the advancement of the "14th Five-Year Plan" for the construction of national medical centers and regional medical centers, it is expected that more hospitals will introduce such advanced equipment in the future, providing world-class hyperbaric oxygen therapy services to a broader range of patients.

Il titanio (Ti), noto per le sue proprietà robuste e le sue applicazioni di ampio respiro, è il nono elemento più abbondante nella crosta terrestre e il quarto tra gli elementi metallici.Simboleggiato da "Ti" e che occupa il 22° posto sulla tavola periodica con un peso atomico di 47.90Il titanio è principalmente ricavato dal rutile e dall'ilmenite che si trovano nelle sabbie delle spiagge, estratte principalmente in Australia e in Sudafrica.

Il processo di produzione inizia con il rutile combinato con coke o catrame e gas cloro, riscaldato per ottenere tetracloruro di titanio (TiCl4).Questo composto subisce una conversione chimica in un materiale simile a una spugnaI gradi legati comprendono gli agenti di lega aggiunti durante la compattazione.I lingotti ottenuti vengono trasformati in vari prodotti di fabbricazione utilizzando attrezzature standard per la lavorazione dei metalli.

Le caratteristiche metallurgiche del titanio lo rendono indispensabile in diversi settori, tra cui l'aerospaziale, la difesa, la lavorazione industriale e chimica, le applicazioni mediche,industrie navali e marittimeInizialmente fondamentale nell'aerospazio militare per le sue qualità strutturali superiori e il suo rapporto resistenza/densità, la densità del titanio varia da 0,160 lb/in3 a 0..175 libbre/in3, variabile a seconda del grado.

La chiave dell'attrazione del titanio è la sua naturale formazione di una pellicola di ossido simile a quella ceramica quando è esposta all'ossigeno, conferendo una resistenza eccezionale alla corrosione e all'erosione.Questo strato di ossido auto-rimediante attenua i graffi in contatto con l'ossigeno.

Biocompatibile, il titanio è ampiamente utilizzato in impianti medici come protesi dell'anca e del ginocchio, casi di pacemaker, impianti dentali e piastre craniofaciali.capacità di mantenere la resistenza ad alte temperature, elevato punto di fusione, ottimo rapporto resistenza/peso, resistenza alla corrosione in diversi ambienti ossidanti (compresa l'acqua salata e salata),e basso modulo di elasticità sottolineano ulteriormente la sua versatilità.

In conclusione, la miscela di resistenza, resistenza e adattabilità del titanio ne conferma lo status di materiale essenziale in vari settori.promettendo una continua innovazione e applicazione in futuro.